Excavation system and quality assurance

Excavation systems

Excavation system and quality assurance

Read more about DBB Dredging

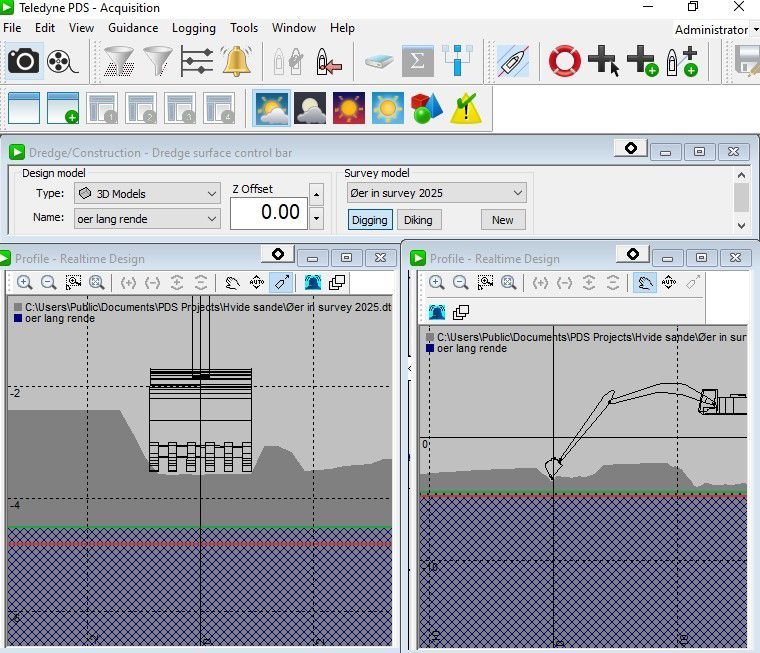

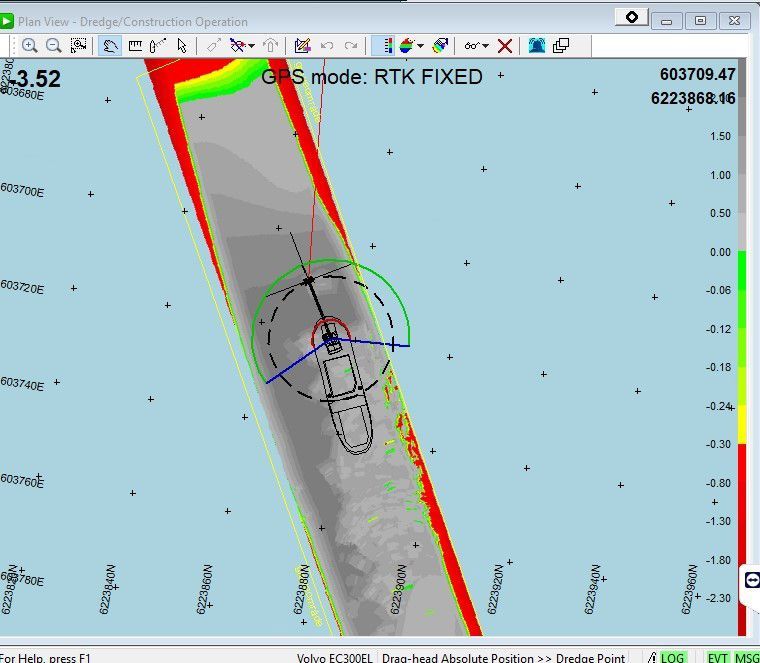

All our excavators have the PDS-2000 excavator system installed, which has been developed specifically for digging under water and is very precise. It can also be used for investigations and soundings.

At the start of an excavation project we arrange to have all the data, soundings and coordinates transferred, so that we can see what result is required. We then prepare a number of data models in AutoCAD, which the client has to approve. The data models are then transferred to the excavators’ computer. The excavator operator can view a visual profile of the project. The consists of a sounding plan showing the current seabed. When the bucket begins to remove material, this is also shown visually on the operator’s computer. All positions for the ship, the excavator and the bucket are logged in a database, so the operator can constantly monitor where and how far down the bucket has been.

We also use the excavator system when building piers. Once we have entered how much the bucket holds, what the material is, and whether it is solid or liquid – the computer continuously constructs a graphic model of the pier every time we lay a bucket of rock. This allows us to see very precisely that the core of the pier is position exactly as it should be.

The project manager at the office in Svendborg can monitor everything the excavator operator does in real time on his computer. He can adjust the data in the excavator’s computer if necessary.

The excavator system operates without any onshore stations or bases, as it uses Leica’s SmartNet, which is consists of a network of more than 50 masts in Denmark. The masts broadcast DVR-90 corrections, so wherever we are in Denmark, the height matches the water level. This happens fully automatically.

The PDS-2000 excavation system thus enables us to ensure the quality of our projects.

Project documentation

We can provide documentation for the client, containing 3D graphics of the finished project. All the documentation is based on the data that the excavators log as XYZ coordinates. There is a journal for the project, recording how it has been done.

For example, if the project involves a new pier, we can show how the berms or core have been laid using 3D graphics. We can also show cross sections and stations from where we have laid the material, so that the client can see how things look at station numbers 300, 305 or 310, etc.

We can provide the documentation as data in XYZ coordinates, or we can build models using 3D graphics.